Adidas recently unveiled their 100% recyclable shoe called the Futurecraft Loop after more than 6 years of research and development. This is a great advancement from our friends in the sports manufacturing industry. We hope many more companies follow Adidas and Brock’s commitment to closed-loop recycling efforts.

The Futurecraft Loop joins a line of other Adidas Futurecraft products, including a shoe made from ocean waste, that have reportedly net $1 billion. However, the Futurecraft products aren’t initially designed to be highly profitable. Instead, they are “statements of intent,” that allow Adidas designers to push footwear forward.

The most challenging part of creating the Futurecraft Loop was designing a shoe for a circular life cycle. Recycling shoes has been a challenge for footwear manufactures, since they are typically made of many different materials that can be difficult to separate. To solve this problem, the Loop is made from a single material, thermoplastic polyurethane. When the original shoes are worn out, they will be given back to Adidas, ground up into pellets, melted down, and used to create a brand new pair.

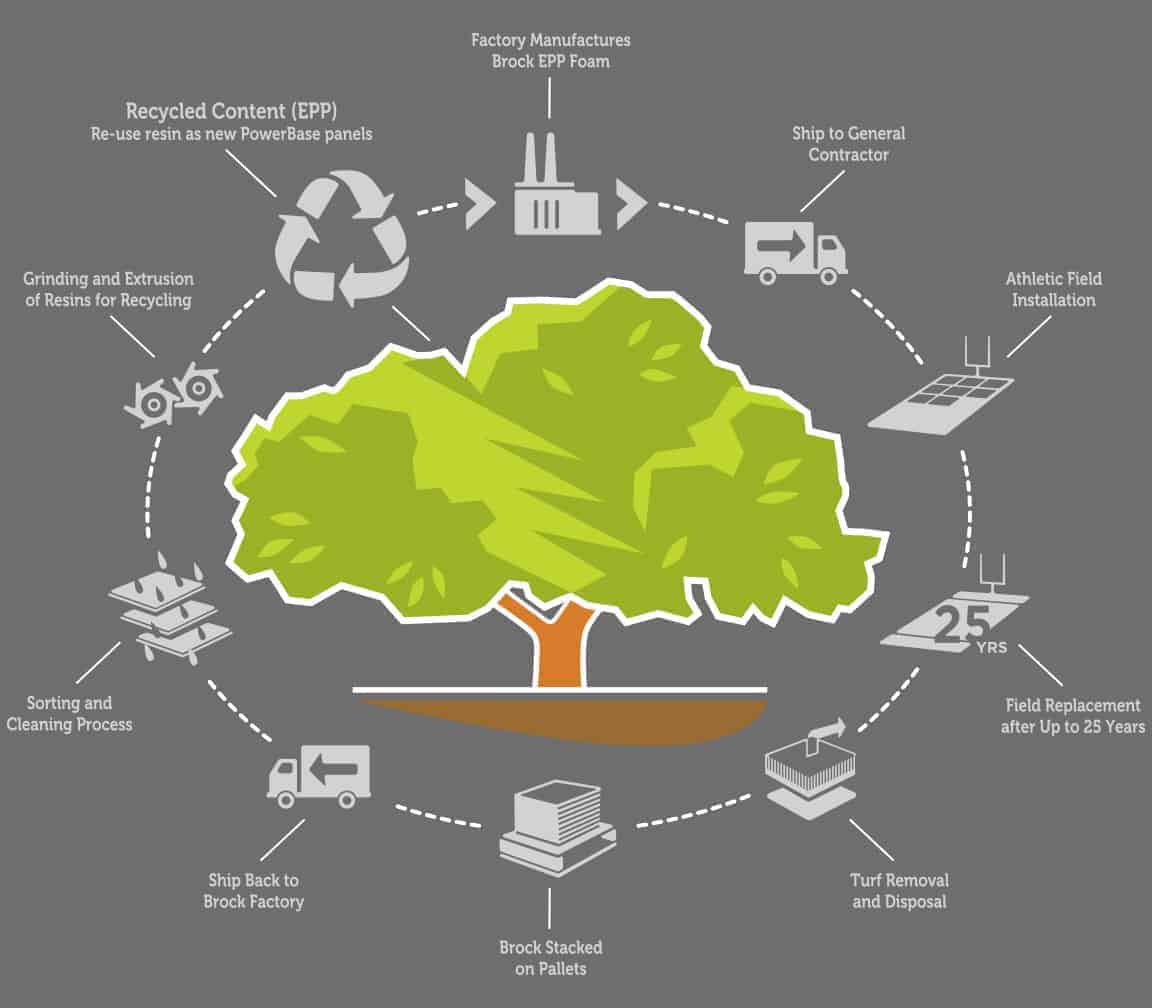

This process is similar to the Cradle-to-Cradle certification, where the concept of waste is completely eliminated. Brock PowerBase is the first shock pad in the industry to be certified Cradle-to-Cradle. Much like the Adidas Futurecraft Loop designers, Brock engineers stress that when it comes to throwing things away, there is no real “away.” Instead of being sent to a landfill, Brock PowerBase shock pads are sent back to the factory, processed, cleaned, ground into pellets, and reused to make new shock pads.