Trees are some of the most steadfast natural structures globally; owing to their particularly strong and durable cell walls, they can withstand extraordinary stresses in the natural environment. This characteristic makes wood a natural choice for so many current applications and for the development of BrockFILL. There aren’t any additives or modifications that make BrockFILL more durable; it’s just wood doing what it does best.

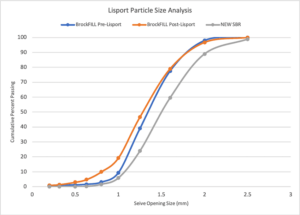

Once Brock determined that wood was a promising candidate for infill development, laboratory testing became the logical next step. Effective product development requires rigorous testing, and for our infill, durability is of chief concern. Primarily, infill durability is measured through particle size analysis. Particle breakdown is the best measure of particle durability, and analyzing particle size distributions is the best way to characterize that change. ASTM has not currently set forth a standard for testing infill durability, so many testing results are proprietary. Primarily, this testing is performed with the Lisport Classic machine, which is designed to simulate turf wear in the highest traffic zones of an artificial turf field. By evaluating the infill from these test samples, Brock can assess the wear BrockFILL would experience under these same circumstances.

To simulate turf wear, the Lisport machine uses a pair of large weighted cylinders that roll over and shear the test sample. The cylinders have cleats protruding from their surfaces and are connected using gears and a chain. In the same way, a bicycle’s pedals drive its rear wheel, the lead cleated cylinder rolls over the surface of the turf and causes the trailing roller to slip as it moves over the turf surface. This creates a shearing action similar to an athlete’s foot turning or accelerating through the turf fibers. As the rollers traverse the turf sample, the tray containing them translates perpendicular to the rollers, further increasing the cleats’ shearing through the turf.

After performing the requisite number of cycles on the plot sample, the infill is collected and evaluated for size and appearance. Size evaluation is reported as a particle size distribution. The figure below shows the results from independent lab testing of BrockFILL and compares them to crumb rubber without any wear testing.